Bar Specified Diagnostic and Repair Training

If you Purchased the paperback it will be mailed out to you usually the next day.

If you purchased the ebook the code and the link to the book will be emailed to you the same day.

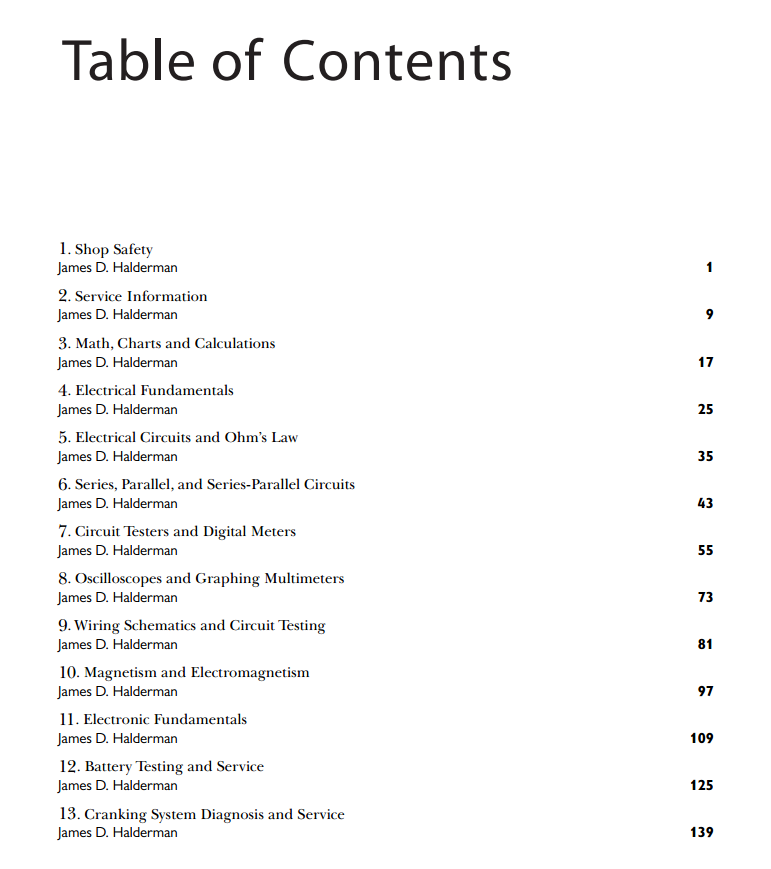

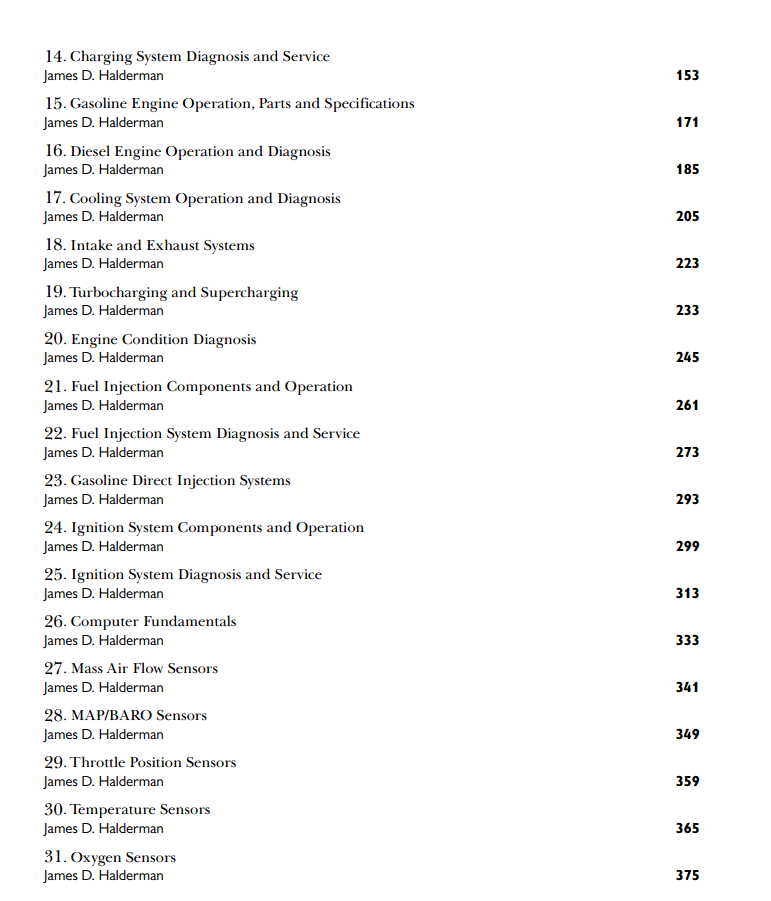

Covers A6, A8, and L1

Shop and safety

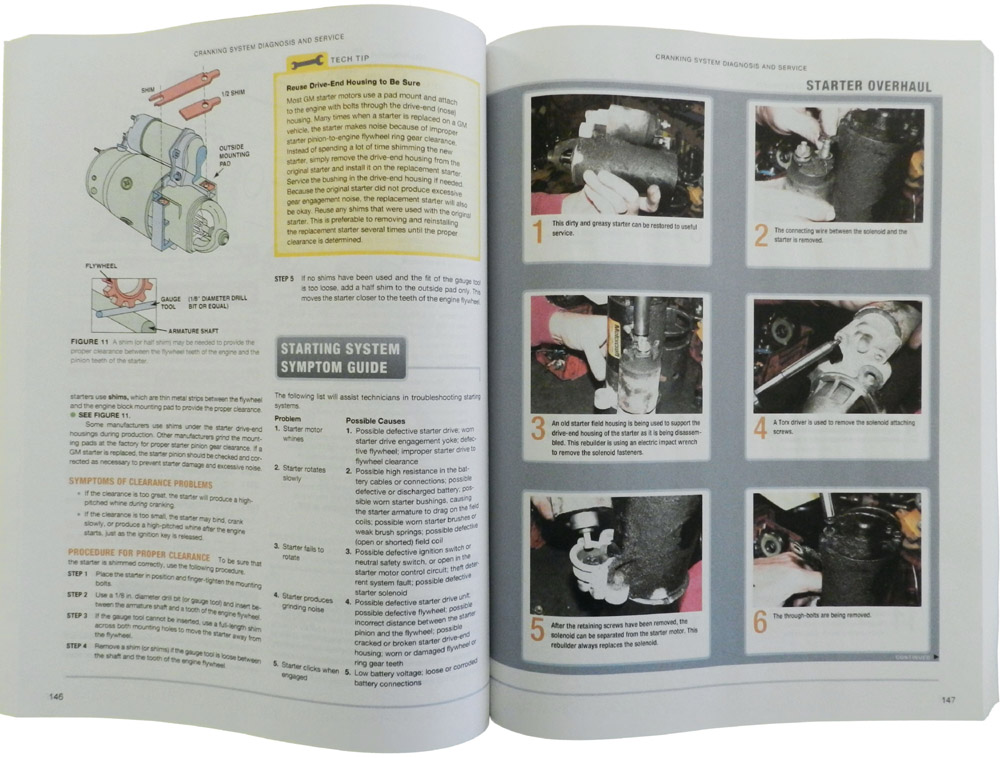

Describe and demonstrate personal, shop, equipment, and vehicle safety practices. Explain the causes and effects of air pollution as it relates to the automotive industry. Explain the standards of practice for Smog Check licensure. Locate, assess, and apply vehicle service/repair information, in the process of Smog Check diagnosis and repair. Employ appropriate diagnostic and repair processes based on the customer’s complaint, the cause of inspection failure, or vehicle data/information. Establish a level of priority concerning the repair of a Smog Check failure using inspection and vehicle data/information.

Electrical/Electronic Systems

Describe the principles of electricity and electronics. Define electrical terms of watts, voltage, current, and resistance. Describe and identify the types of automotive electrical circuits (series, parallel, and series/parallel). Describe and identify the types of electrical and electronic components used in computer-controlled automotive systems. Describe the theory, design, and operation of automotive electrical and electronic systems. Identify standard electrical and electronic symbols. Demonstrate a full understanding of electrical principles in detecting defects in electrical/electronic circuits, including, but not limited to, continuity tests, resistance tests, current/amperage tests, and voltage drop tests. Interpret electrical wiring diagrams and schematics to diagnose automotive electrical and electronic systems. Employ various types of test equipment, including but not limited to a digital multi-meter (DMM) and a digital storage oscilloscope (DSO).

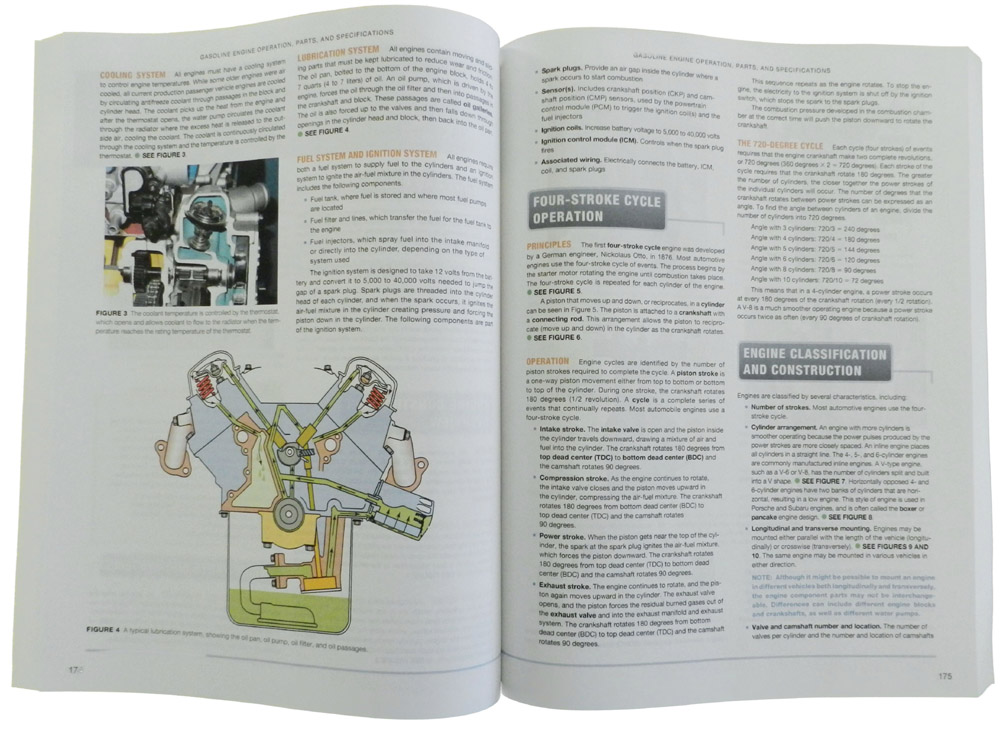

Engine and Emission Control Performance

Describe engine theory, design, and operation. Describe the theory, design, and operation of induction and exhaust systems. Describe the theory, design, and operation of fuel systems. Describe the theory, design, and operation of ignition systems. Describe the theory, purpose, design, and operation of emission control systems, including, but not limited to, crankcase controls, fuel evaporative controls, air injection, exhaust gas re-circulation, catalyst and other exhaust gas after-treatment systems, and integrated emission control management strategies, such as spark control and variable valve timing. Describe the exhaust byproducts of internal combustion and define the primary emissions resulting from this combustion process. (Oxygen, carbon dioxide, carbon monoxide, hydrocarbon, oxides of nitrogen, sulfur dioxide, particulate matter). Explain the relationship of the air/fuel ratio to the combustion process and the resulting emissions (stoichiometric, rich, and lean). Analyze exhaust gas readings to determine the best diagnostic strategy (4 - 5 gas analysis). Employ engine and emission control diagnostic test equipment, including, but not limited to, cylinder compression gauge, cylinder leak down tester, fuel pressure gauge, ignition oscilloscope, timing light, pressure/vacuum gauge, DMM, OBD diagnostic scan tool, DSO, and exhaust gas analyzer. Diagnose engine mechanical malfunctions or defects and determine appropriate repairs. Diagnose induction and fuel system malfunctions or defects and determine appropriate repairs. Diagnose emission control systems malfunctions/defects and determine appropriate repairs. Including, but not limited to, crankcase controls, fuel evaporative controls, exhaust gas recirculation, secondary air, and catalytic converter efficiency. Diagnose ignition system malfunctions or defects and determine appropriate repairs. Identify root or underlying causes of engine and emission control malfunctions differentiate between mechanical, electrical/electronic, and fuel system problems, and determine appropriate repairs. Describe the theory, design, and operation of computerized engine and emission control management systems, OBDI and OBDII.

Identify computerized engine and emissions control systems, subsystems, and components. Describe OBDII monitors: catalyst efficiency, misfire detection, fuel system, heated exhaust gas oxygen sensors, EGR, and comprehensive component monitors, evaporation emissions, secondary air injection, thermostat, and PCV monitor. Describe the OBDII system modes of operation, modes 1-9. Evaluate a vehicle’s OBD data, to determine the system's operational status and condition, including, but not limited to, supported monitors, monitor enabling criteria, monitor readiness, generic and vehicle manufacturer fault codes, freeze frame data, and fuel control. Demonstrate comprehensive knowledge and ability in using an OBDII diagnostic scan tool to detect various engine and emission control malfunctions. Demonstrate comprehensive knowledge and ability in using a DSO to detect various system/component malfunctions. Evaluate a vehicle’s OBD data to verify proper engine/emission controls management functionality- repair verification.

The instructor's version comes complete with multimedia power points, labs, and tests. Everything you need to put on a professional class.